How UNIDO is helping Egypt tackle climate change one motor at a time

As Egypt’s economy continues to grow, so too does its energy consumption. While efforts to curb household energy use and incentives to boost the renewables market are useful, more measures are needed in the face of climate change. One untapped opportunity to make a significant dent in the country’s energy consumption lies with the humble industrial motor.

Required for everything from driving core industrial processes as well as auxiliary systems such as compressed air generation, ventilation and water pumping, motors are a ubiquitous and often hidden component in industrial processes.

In Egypt, more than one million motors are responsible for driving the country’s economic growth through the production and processing of goods such as textiles, pharmaceuticals and food products. Yet, many of Egypt’s motors are old and use more electricity than required. This is contributing to unnecessary emissions being released into the atmosphere. According to the “Egypt: Improve Efficiency” report by the World Bank, most industrial processes and equipment in Egypt consume 20 per cent or more energy than international best practices.

The climate link

Worldwide, electric motor-driven systems (EMDSs) account for between 43 and 46 per cent of the global electricity consumption (Stoffel, 2015). Therefore, they offer the largest saving opportunity in the industrial electrical energy efficiency market. Improving the energy efficiency of an industrial plant’s outdated motor system is one of the fastest ways a company can reduce carbon emissions.

In Egypt, the three main electric motor-driven systems —industrial pump systems, fan systems, and compressed air systems— together account for 45 per cent of electricity use in industrial motor systems. Motor system optimization measures, including low and no-cost measures, combined with motor replacement could result in over 40 per cent total technical electricity savings potential (IEA, 2016).

Learn more about motor system optimization |

Although only accounting for 0.75 per cent of the total greenhouse gas (GHG) emissions worldwide, Egypt is one of the fastest-growing emitters in the world and one of the most vulnerable regions to climate change. Overhauling the industrial sector’s motor-driven systems is one way Egypt can turn this trend around.

Motors: The next frontier in Egypt’s industrial energy efficiency journey

Over the past decade, UNIDO Egypt has convincingly demonstrated the benefits of various industrial energy efficiency interventions. Thanks to the investment, awareness-raising and training delivered by the UNIDO team, more than 3.58 metric tons of CO2 have been avoided, more than 700 local expert consultants have been trained and companies like petrochemical manufacturer SIDPEC are enjoying annual energy cost savings of more than USD $500,000.

Having significantly accelerated demand for energy management system optimization, the time has come to tackle the country’s fleet of aging industrial motors. But this is no easy feat.

The adoption of energy-efficient motor-driven systems in Egypt remains low as industry has historically enjoyed subsidized energy prices. The market is saturated with low-cost, low-efficiency and counterfeit motors. A survey conducted by the IFC STEP project revealed that over 60 per cent of installed motors were below standard efficiency and more than half are over 10 years old. Only 24 per cent of the surveyed motors had variable speed drives installed on them.

Replacing aging motors, with more efficient models requires significant upfront costs and plat downtime in some cases. But over time, the energy cost savings achieved outweigh the initial investment required to upgrade. Currently, most plant managers are more inclined to repair their motor as much as possible, a practice which often erodes efficiency even further.

“Our first step has really been promoting the compelling business case for investing higher quality motors,” explains programme manager Gihan Bayoumi.

Until relatively recently, motor technology remained largely unchanged for decades. However, with the drive toward more efficiency worldwide, motors that use less energy and contribute to lower emissions are finding their way onto the market.

But in order to reap the most benefits, energy efficiency must go beyond the motor itself.

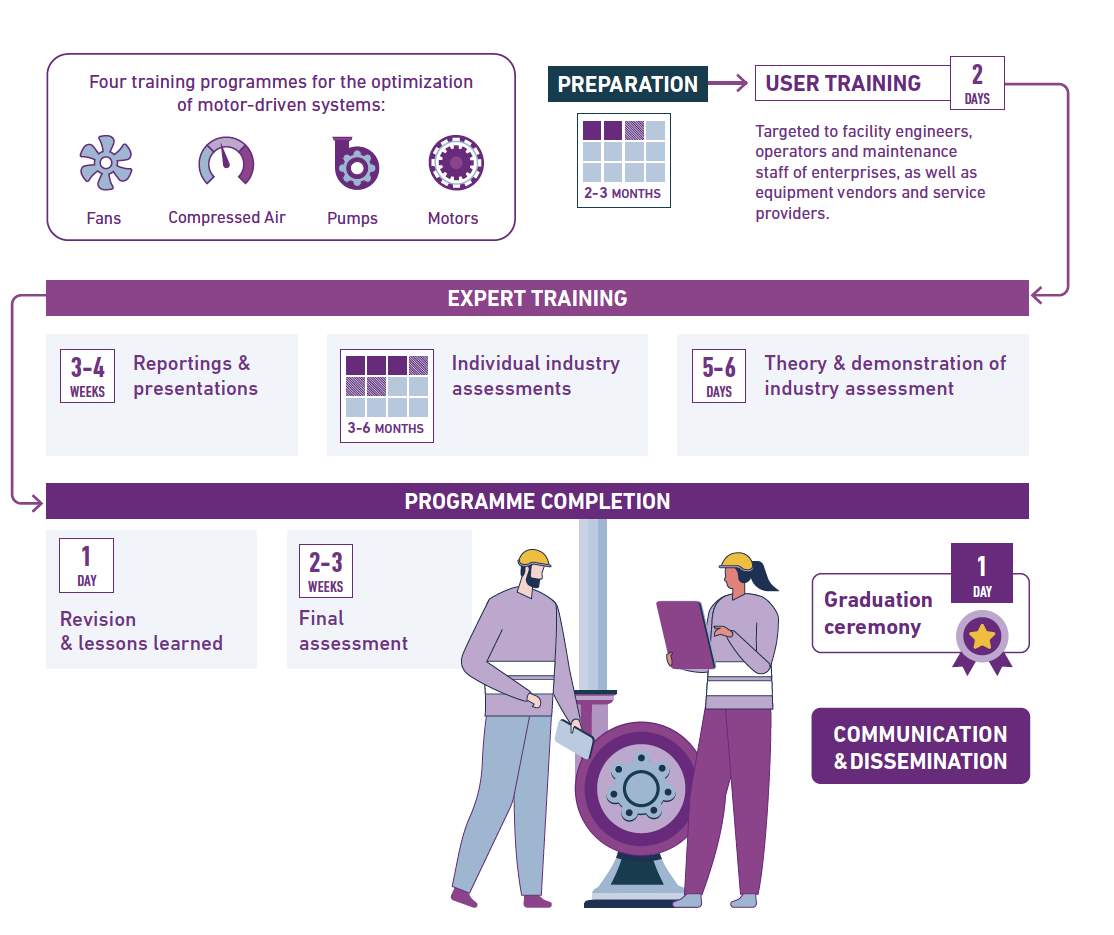

“An efficient electric motor and the use of variable speed drives is of little value if pipes are blocked in a pump system, or if there are leaks in a compressed air system. This is why UNIDO’s training addresses the entire motor system, from the power supply to the mechanical controls and everything in between. A motor is considered just one of many opportunities for optimization,” explains Gihan.

DOWNLOAD THE INFOGRAPHIC HERE |

In UNIDO’s experience, cost-effective motor system optimization measures and the replacement of inefficient motors can result in as much as a 20 per cent reduction in energy use. Early participants in UNIDO’s training programmes, which were facilitated throughout 2021, are already seeing results.

Sondos Yehia

“The training explains how to conduct measurement and analysis procedures for specific energy parameters, consequently supplying the market with competent service providers.” – Sondos Yehia,

Alaa Mostafa Abd ElRahim, Energy Efficiency and Solar Water Heating Specialist

“As we all know the world is now working towards the ‘Net Zero Economy,’ providing around 24 million new job opportunities around the world. We, in Egypt, need to be part of this. The program is truly outstanding as it works by building local expert capacity to work competently in this field.” — Alaa Mostafa Abd ElRahim, Energy Efficiency Expert

Dr. Adel T.S Beshara, Managing Director of Global Renewable & Energy Efficiency Solutions (GREESol)

“I really benefitted from this week’s course because it was diverse and included a closer look at the factory level and the importance of energy measurement devices.” — Dr. Adel T.S Beshara, Managing Director of Global Renewable & Energy Efficiency Solutions (GREESol)

Now with a number of industrial champions promoting the virtues of efficient motor system optimization, Gihan has her sights set on the finance sector.

“Without dedicated local financing banking investments into motor system upgrades it will be difficult to achieve the scale required to contribute to national emissions reduction targets,” she explains.

The coming year will see the project rollout more training programmes across the country while simultaneously working with government partners from the Ministry of Trade and Industry.

“Egypt is a global industrial powerhouse. And while many of our industries are categorised in ‘the hard to abate sectors,’ industrial motor efficiency is an opportunity to reduce carbon emissions as technology is developed and commercialised,” adds Gihan.

………………………………

Overall, the first phase of the Global Environment Facility (GEF) funded programme, aims to mitigate 2.5 million metric tons Co2 emissions, equivalent to the emissions generated by 500,000 cars driven over one year.