The true value of your energy savings is more than you think!

If you are reading this article you will most likely be well aware of the financial savings that can be achieved through better energy management and strategic energy efficiency interventions. For years UNIDO has documented countless examples and case studies of industrial organizations, big and small, making tremendous financial savings from a variety of energy efficiency measures. From saving millions of dollars per annum in a Malaysian oleochemical production facility to slashing energy bills in companies across Morocco; the story repeats itself over and over.

However, what if we told you that these energy cost savings are actually only a fraction of the benefits that come from better energy management? In fact research indicates that the majority of industrial organizations worldwide aren’t even recording half of the benefits and value captured through their successful energy efficiency interventions. In many cases the value of the “side-effects” that come from energy saving projects are often several times greater than the energy savings themselves! Let us explain.

Non-energy benefits explained

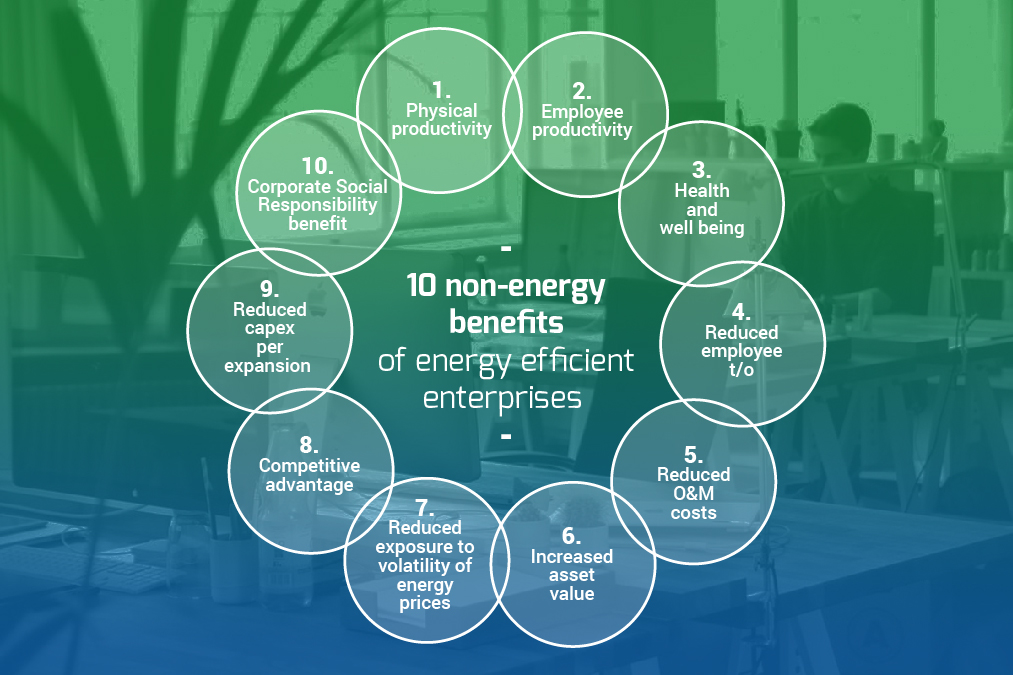

The Multiple Benefits of Energy Efficiency. Graphic credit: Ecrowd (https://www.ecrowdinvest.com/blog/en/multiple-benefits-of-energy-efficiency/).

Energy efficiency improvements can lead to a broad range of impacts, beyond energy cost savings. These additional impacts are often referred to as non-energy benefits (NEBs) or the multiple benefits of energy efficiency. Over the years UNIDO, the International Energy Agency and partners have conducted a series of in depth analyses into non-energy benefits which range from enhanced productivity, reduction in local and global pollutants, better working environments for employees, improved product quality and enhanced business competitiveness as well as job creation and better health outcomes for society at large.

While including NEBs in a business case may seem a little more abstract than standard profit versus loss accounting decisions, there is still a clear investment decision to consider. Take the benefits of improved production practices through better and more systemised energy management as an example. More efficient equipment or operation processes can lead to shorter process times and use of lower cost factors of production (labour, water, waste, materials), which can enable higher product output. This was the case for Scanola, a Danish rapeseed processing company, whose non energy benefits included an increase in production capacity by 30-35 per cent.

In addition to energy savings costs, Danish rapeseed processor Scanola managed to improve its production capacity as a whole in large part thanks to more efficiency equipment and processes implement through an improved energy management system.

Optimising processes or upgrading equipment also offers additional benefits achieved through energy efficiency. It can defer the need for capital costs in replacing equipment and also lead to situations where certain equipment is no longer needed. This was the case in one petrochemical company in Africa which discovered, through an energy use and monitoring assessment, that one of its three water pumps could be discontinued, thereby eliminating maintenance costs for that piece of equipment as well as unnecessary energy costs.

Improvements in product quality are another economically important NEB which often fly under the radar. One Swedish clothing company, which replaced halogen lighting with LED lighting, found that it not only saved energy and money, but the stock on the showroom floor faded at a lower rate thanks to the LEDs, thereby reducing product waste among many other benefits.

Increasingly, as incentives, subsidies and in some cases financial penalties are ushered in to promote environmentally friendly best practice among industrial organizations, companies that invest in energy efficiency are also set to reap positive financial rewards and access to finance with more competitive rates.

Then there are also positive unintended consequences of energy efficiency improvements which catalyse even further energy and cost savings as a result. For example, a major Danish food company carried out an upgrade of its boiler room insulation. Once the upgrade was complete the boiler room temperature dropped so much that it was no longer necessary to have an open door to maintain bearable working temperatures. This not only improved working conditions for employees but also mitigated the risk of pests such as rats entering the facility through the open door. The lower room temperature also resulted in less wear on the switchboards and thus lower maintenance costs.

An ‘energy freak’ reformed

For over two decades Erik Gudbjerg, a Danish energy engineer by training, has been championing the added benefits of energy efficiency. While using NEBs as unique selling points to encourage organizations to invest in energy efficiency seems obvious to him now, it wasn’t initially.

Erik Gudbjerg, a Danish energy engineer and energy management trainer, is calling on fellow engineers and industrial production managers to value and consider the non energy benefits of industrial energy efficiency.

“It wasn’t until a friend of mine in the field stopped me and asked: ‘Have you actually asked yourself if energy efficiency is the most important thing to all companies?,’” Erik explains.

“I was so thrilled about energy efficiency and I thought well it should be easy to convince people and companies to make energy savings. But in reality, what was important to me wasn’t necessarily important to them.”

This partialness to promoting energy efficiency and the technical mechanics behind it is still a common barrier among energy consultants, many of whom come from specialised and scientific backgrounds like engineering. Erik refers to them as “energy freaks.”

“I myself am an engineer, so I’m shooting myself in the foot by saying we are ‘energy freaks’ because we have been so devoted to how much energy we can save. We haven’t been focusing on the other positive side effects because it’s not something we are typically, or traditionally as engineers, interested in.”

According to Erik it’s critical for energy management and efficiency consultants to start by asking the company what’s actually important to them. “What are their challenges? What is the vision and mission of the company? It’s an opportunity to align energy management services and the benefits with a company’s overall objectives. It’s also very important in convincing higher management of why they should invest in energy efficiency,” explains Erik.

It’s also crucial that energy management consultants are aware of who they are talking to, says Erik.

“If they are talking to business management, the pitch needs to be completely different to if they are talking to a process manager.”

The C-suite level, for example, may be more interested in the bottom line of the company, or corporate social responsibility or enhanced competitiveness. Whereas the plant manager might be more convinced by higher performance, reduced instances of break down and safer working environments for staff. A finance manager might want to talk in terms of net present value or internal rate of return for a specific energy efficiency project.

“In my experience with NEBs, more often than not, you can find the unique selling point for energy efficiency,” adds Erik.

Measuring the true value of your energy savings

Work to date indicates the value of non-energy benefits can be in the range of 40-50 per cent of the value of energy savings per measure or as much as 2.5 times the value of energy savings (Lilly, P. and D. Pearson, 1999; Pearson and Skumatz, 2002). However, it’s not always easy to calculate the value of these benefits, especially when Energy Measurement and Performance Indicators used by organizations are simplistic and restricted to financial assessments in the short term (e.g. simple payback; rate of return). Even when more sophisticated investment analysis frameworks are used, such as net present value, these approaches still don’t typically account for the value of non-energy benefits. This leads to an underestimation of the economic potential of industrial energy efficiency measures and of their potentially transformative impact on business processes and productivity. Likewise, the benefit-cost ratio of industrial energy efficiency policies is routinely underestimated when non-energy benefits are excluded from policy appraisal and evaluation.

Non energy benefits and their impact to the bottom line aren’t always considered by technical staff and engineers who heavily focus on energy consumption and related cost savings.

“As an energy manager in a company, it is natural to focus on energy saving and the resulting payback time. But by keeping an eye on all the other effects of an investment in energy efficiency, a broader picture of the benefits and possible disadvantages of the investment can be obtained,” explains Erik.

In order for the true value of NEBs to be realized and recognized, it’s essential for them to be carefully assessed, measured and monitored. This often requires a deliberate change of culture in an organization which fosters a company appreciation for NEBs.

While it can be difficult to accurately measure NEBs as they aren’t always quantitative in nature, it’s nevertheless possible and important to capture the relative size of the NEB (e.g. very large, larger, same as the energy efficiency improvements, smaller, much smaller). Another useful way to demonstrate the value of NEBs is by applying an index. This avoids having to translate all NEBs into an exact monetary value. A project may for example have resulted in significantly reduced noise levels in the factory workshops and the client may judge the reduction just as valuable as energy savings. Doing this requires companies to think beyond strict energy savings as a measure of progress and value.

|

1) To learn more about NEBs and how to measure them see the resources below and visit the Industrial Energy Accelerator’s dedicated resource library at https://www.industrialenergyaccelerator.org/iea-posts/resources/. 2) The Danish LFORSK Programme developed a database of more than 100 examples where energy saving projects have led to NEBs. Categorized into organizational areas and themes, the database makes it easy for companies to find comparable examples to their own projects and industries. 3) UNIDO’s Industrial Energy Accelerator has a growing library of easy to read and share case studies which detail exactly how industrial organizations achieved benefits such as emissions reduction, improved product quality and enhanced competitiveness. Read more about how the Accelerator is working to improve energy management in industrial organisations worldwide: Our work |