Industrial Heating Solutions

The heat is on to tackle climate change with energy system optimization.

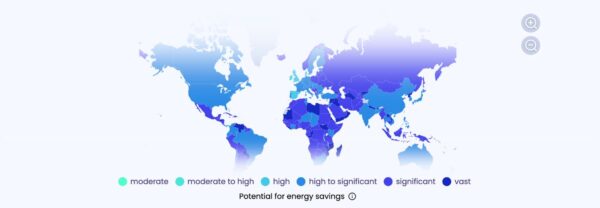

Industrial heating and steam systems require large amounts of energy. Yet despite making up almost one-fifth of global energy consumption, industrial heat processes are often overlooked in the effort to reduce costs and emissions. Considering that the vast majority of industrial heat originates from fossil-fuel combustion, it is critical for organizations to take advantage of the many opportunities that improve energy efficiency in industrial heat processes.

What are the benefits?

One of the major goals of a heat and steam process energy assessment is to help industry identify, quantify and act on relevant energy saving opportunities. Often this leads to the classic question of: What is the return on investment (payback) for implementing efficiency interventions, new technologies and/or processes? In many cases investments into heat system efficiency improvements can be recouped in less than two years thanks to energy savings which range from 2 to 30 per cent. This has enabled many organizations to remain profitable and competitive in globalized markets.

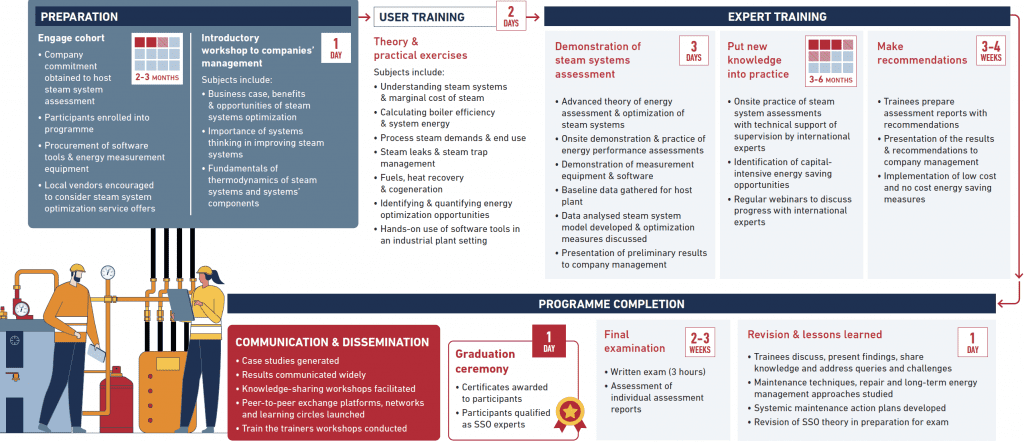

UNIDO’s approach

UNIDO has long championed a ‘systems’ approach to achieving efficiency rather than focusing on the maintenance of individual components.

UNIDO’s Steam System Optimization (SSO) programme was born out of a deep understanding of efficiency opportunities generated through countless steam system analyses conducted in plants around the world. What has emerged over the past 10 years is a flagship steam system optimization training programme which is responsible for producing great national champions for industrial energy efficiency and steam system optimization.

Meet the experts

Greg Harrell

Engineering Programs Director | Miligan University

“If we want to target big energy users around the world, industry is it. And if you want to target big energy users in industry, steam and process heating are the big players in the game.”

Alfred Hartzenburg

Project Leader | National Cleaner Production Centre of South Africa

“We all run to the boiler house. The great gleaming set of boilers seems to be the obvious place to look for efficiency opportunities. But we really don’t consider deeply enough just how we are using steam or heat within the context of the entire system. Thinking in this way is how organizations unlock some of their biggest energy savings.”