Industrial Cooling Systems

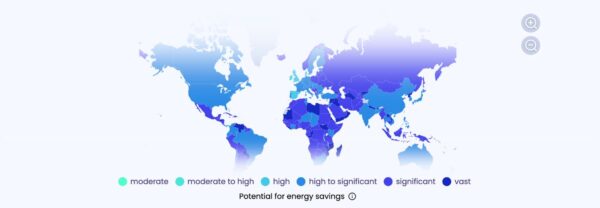

Energy consumed by residential, commercial and industrial cooling systems is predicted to outpace that of heating in the coming decades.

Until recently, industrial cooling systems have somehow managed to fly under the climate change radar. When it comes to energy efficiency most people tend to think of energy in terms of heat, light or transport. However, in a somewhat peculiar irony, cooling systems are emerging as one of the leading contributors to global warming.

It is imperative for industry to pay more attention to the growing demand for cooling. Simple and often low-cost cooling system optimization solutions can dramatically slash industry energy bills and emissions as a result.

What are the benefits?

Aside from the multiple environmental benefits that come from cooling and refrigeration system optimization, current state-of-the-art technology and best practice knowhow can lead to energy savings of more than 15 per cent with none or minimal capital investments. The money saved goes directly to the organization’s bottom-line. In UNIDO’s experience some companies have achieved more than 30 per cent of energy savings through cooling system optimization. Such savings offer numerous, and often indirect, benefits including system reliability, a boost to staff morale, reductions in workplace safety hazards and an overall elimination of harmful pollutants.

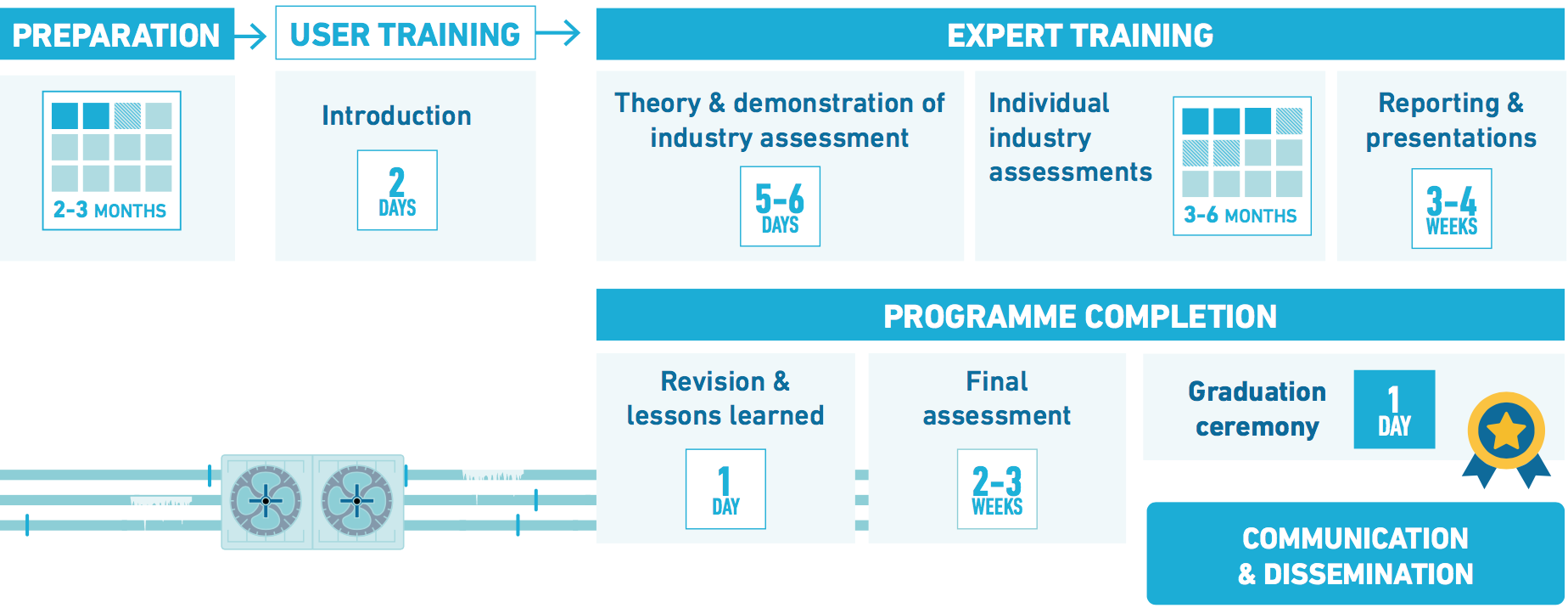

UNIDO’s approach

As energy demand for cooling threatens to make our planet even hotter, UNIDO is gearing up in this critical time to support industrial organizations as they unlock the huge energy saving potential within their cooling and regeneration systems.

Being a technology and vendor agnostic organization, UNIDO is able to deliver impartial technical training and guidance to companies and related government departments. As a global implementing agency of the Kigali Amendment to the Montreal Protocol, UNIDO is well positioned to simultaneously assist industries in low-middle income nations and emerging economies transition toward energy efficient and climate friendly refrigerant (HFC) alternatives.

Meet the experts

Riyaz Papar

Cooling systems expert & trainer | Texas, US

“We all have to play a part in creating a sustainable planet for generations to come. Realize that our cooling and refrigeration systems will always be needed. So why not make them efficient and do our bit to ensure that these systems continue to run reliably and at the same time minimize our carbon footprint.”

Khaymar Khine

Executive Director | Devi Daiichi Joint Venture | Myanmar

“In addition to the energy savings achieved with support from UNIDO’s Industrial Energy Efficiency project in Myanmar, we now have so much more peace of mind thanks to the reliable and more consistent cold room temperature achieved through system optimization. This alone is a huge benefit”